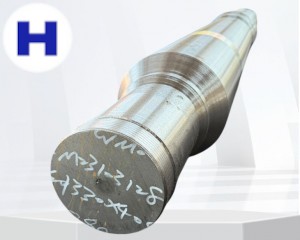

316 Forging Steel Roller Shaft

Short Description:

Discover Forging Steel Roller Shafts for industrial applications. Custom made to your specifications, with durable performance and precise forging.

Forged Steel Roller Shaft

Forged Steel Roller Shaft is a high-strength, durable component used in various industrial applications, particularly in the manufacturing and processing of materials such as metal, paper, and textiles. Manufactured through the forging process, these shafts offer superior mechanical properties, including improved toughness, resistance to wear, and higher load-bearing capacity compared to cast or machined shafts. Forged Steel Roller Shafts are custom-made to meet specific size, shape, and performance requirements, ensuring reliable operation and extended service life in heavy-duty environments. Ideal for use in rollers, conveyors, and other machinery, they provide exceptional performance in high-stress conditions.

Specifications Of Forged Steel Rolls:

| Specifications | ASTM A182,ASTM A105,GB/T 12362 |

| Material | Alloy steel,Carbon steel,Carburizing steel,Quenched and tempered steel |

| Grade | Carbon Steel:4130,4140,4145,S355J2G3+N,S355NL+N,C20,C45,C35,etc. |

| Stainless Steel:17-4 PH,F22,304,321,316/316L,etc. | |

| Tool Steel:D2/1.2379,H13/1.2344,1.5919,etc. | |

| Surface Finish | Black, Bright, etc. |

| Heat treatment | Normalizing,Annealing,Quenching&Tempering, Surface Quenching,Case hardening |

| Machining | CNC Turning,CNC Milling,CNC Boring,CNC Grinding,CNC Drilling |

| Gear Machining | Gear Hobbing,Gear Milling,CNC Gear Milling,Gear Cutting,Spiral gear cutting,Gear Cutting |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

Forging Steel Shaft Applications:

1.Steel Industry: Forged Steel Roller Shafts are extensively used in rolling mills, where they play a critical role in shaping and forming metal products. These shafts withstand high forces and temperatures, ensuring smooth and consistent metal processing.

2.Paper and Pulp Industry: In paper mills, these shafts are used in calenders, presses, and rollers, which are essential for the production of paper and cardboard. Their durability and resistance to wear make them ideal for handling high-pressure and high-speed operations.

3.Textile Industry: Forged Steel Roller Shafts are used in textile machines, such as weaving and spinning equipment, to support rollers and provide precise movement and stability during fabric production.

4.Mining and Quarrying: These shafts are critical in machinery that processes minerals, where they endure heavy loads and harsh operating conditions. Their strength ensures long-term reliability and efficient operation in crushers, mills, and conveyors.

5.Agricultural Equipment: In agricultural machinery, such as harvesters and threshers, Forged Steel Roller Shafts help in the transfer and movement of materials, ensuring the efficient operation of equipment under demanding field conditions.

6.Automotive and Conveyor Systems: Forged Steel Roller Shafts are used in automotive manufacturing lines and conveyor systems, where they provide robust support for heavy-duty rollers that move products along the assembly line.

7.Plastic and Rubber Manufacturing: These shafts are used in extrusion machines and other processing equipment in the plastic and rubber industries, ensuring high performance in environments where consistent speed and load-bearing are required.

Features of Bright Shaft Forgings:

1.High Strength and Toughness:The forging process enhances the steel's internal grain structure, making the shaft significantly stronger and more resilient to stress and impact.

2.Improved Wear Resistance:Forged Steel Roller Shafts are highly resistant to wear and abrasion, making them ideal for heavy-duty applications where friction is constant.

3.Enhanced Fatigue Resistance:Due to their refined microstructure, these shafts can withstand repeated loading and unloading cycles without fracturing or losing integrity.

4.Superior Load-Bearing Capacity:Forged Steel Roller Shafts are designed to handle heavy loads without deformation.

5.Corrosion Resistance:Depending on the grade of steel used and any additional surface treatments (e.g., coating or heat treatment).

6.Customizability:Forged Steel Roller Shafts can be tailored to meet specific size, shape, and performance requirements.

7.High Temperature Resistance:These shafts can perform in extreme temperature conditions.

8.Dimensional Accuracy:The forging process allows for tight tolerances and high dimensional accuracy.

9.Durability and Longevity:Forged Steel Roller Shafts have a longer service life compared to other materials or manufacturing methods due to their superior strength and durability.

10.Impact Resistance:The process of forging improves the shaft's ability to resist sudden shocks or impacts.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS ,TUV,BV 3.2 report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Forged Steel Shafts Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Hongwan Alloy Materials's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,